Austria leads by example

In Austria, we have been committed to the issue of sustainability for more than 20 years now and have received the internationally recognised ISO 14001 certification every year. This confirms that we consistently comply with environmental guidelines and laws and fulfil our ecological responsibility.

Annual targets such as the systematic identification of risks and opportunities or the optimisation of the company’s environmental protection through a continuous improvement process are a permanent feature for the environmental management team in Austria. In addition, we continuously set ourselves the target of increasing competitiveness, exploiting potential savings through energy-saving measures and creating more legal certainty and lower environmental risks.

The three strategic key topics that Beyond Gravity has defined comprehensively for the company are already being addressed in Austria. “For example, we had a ’Corporate Carbon Footprint’ (CCF) drawn up for the first time in 2017, and next we would like to examine the lifecycle of our thermal protection foils. It makes me proud that we are already on the right track here in Austria and that my work is considered valuable and meaningful,” says Bettina Hartmann, Specialist Facility & Environment. Bettina has been with the company since 2000. In her current role, she can draw on over 10 years’ experience in the field of sustainability.

"We want to make a contribution that creates sustainable added value."

Successfully implemented measures in Austria

- Switching to electricity from 100% renewable energies

- Continuous energy savings through ongoing technical optimisation of plants and their control, adaptation of processes or the replacement of equipment

- Step-by-step conversion to LED lighting

- Raising awareness for environmentally-friendly behavior among employees, such as switching off appliances at the end of the day and the conscious use of air-conditioning or heating devices in offices and meeting rooms

- Expansion of electromobility: gradual, carefully considered partial conversion to electric cars and the installation of electric charging stations

We have our corporate carbon footprint under control

With the revision of ISO 14001 in 2015 (ISO 14001:2015), the topic of lifecycle assessment was brought intofocus and declared as a standard requirement. To comply with the standard requirement, in 2017 we had a corporate carbon footprint drawn up for the first time. To this end, all three scopes of the Greenhouse Gas (GHG) Protocol were used.

| Scope 1 (Direct emissions) | Emissions from activities owned or controlled by the company. |

| Scope 2 (Indirect emissions) | Emissions from the generation of electricity, steam, heat or cooling, which are acquired by the company. |

| Scope 3 (Indirect emissions) | Various scope 3 categories: purchased goods and services, capital goods, fuel and energy-related activities (not included in scope 1 or 2), upstream transportation and distribution, waste in operations, business travel, employee travel |

The results

"The Corporate Carbon Footprint records all emissions generated by our activities over a year. I am satisfied with the result for Scope 1, as we source electricity from 100% renewable energy. The most potential for improvement currently lies in Scope 3, in the area of mobility. Switching to public transport, reducing business travel and making the workplace more flexible are measures which will contribute to improving the results in the future,” says Bettina Hartmann, Specialist Facility & Environment.

| Scope 1 | 8.89% | 116,724 kg CO2 eq. |

| Scope 2 | 8.66% | 113,787 kg CO2 eq. |

| Scope 3 | 82.45% | 1,082,742 kg CO2 eq. |

| CCF Beyond Gravity Austria | 100% | 1,313,253 kg CO2 eq. |

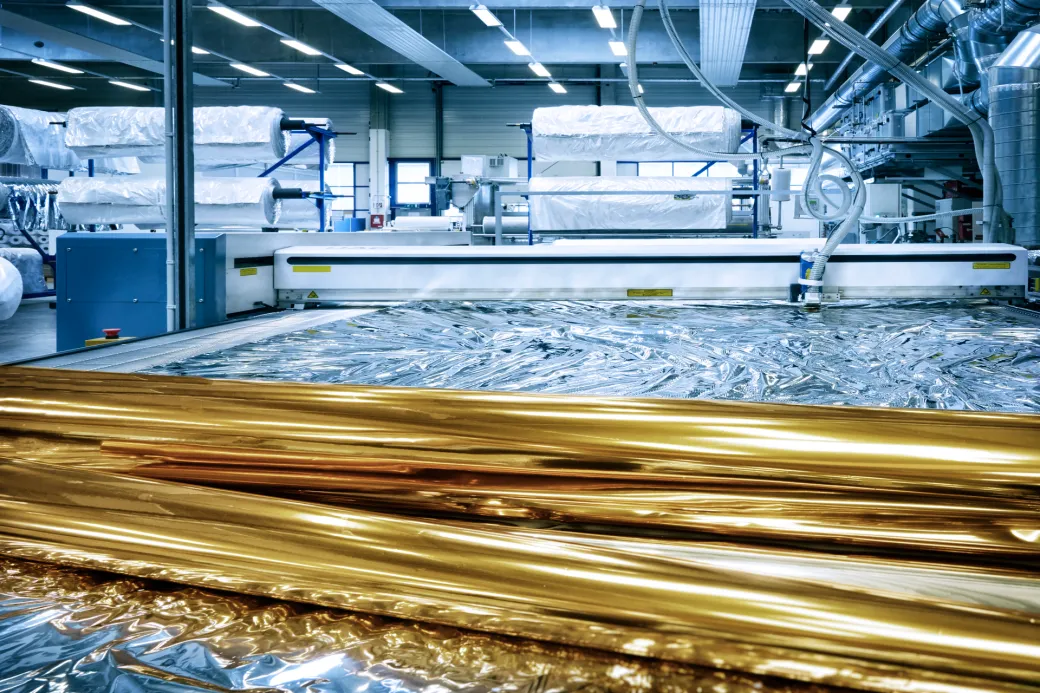

What’s next? Reviewing the life cycle of our thermal protection foils

Interest in the environmental impact of products and services is growing among companies, suppliers, customers and policymakers. One indicator is the product carbon footprint (PCF). It provides information about the total greenhouse gas emissions for which a product is responsible during its life cycle. With relatively little effort, it can be used to identify potential improvements and compare alternatives.

“We not only want to comply with the standards and analyse our corporate carbon footprint, but we also want to make a contribution that creates sustainable added value and take a closer look at individual products. Therefore, as our first project, we are planning on calculating and documenting the environmental impact of the thermal foils which protect satellites from extreme heat and cold in space,” says Bettina Hartmann, Specialist Facility & Environment. The aim of the project is to create a product carbon footprint of our thermal foils using the “cradle to the gate” approach. The carbon footprint is expressed in CO2 equivalents and provides transparent, easy to understand and easily communicable results. The calculation is based on standard ÖNORM EN ISO 14067

We will take into account the relevant raw materials, auxiliary materials and energy sources. The system boundary begins with the production or extraction of the raw materials, materials and consumer goods, including any relevant transport and ends with the delivery to the customer. This will enable us to communicate the total greenhouse gas emissions of our thermal foils as a key figure to all stakeholders should there be interest and demand.

Furthermore, with this evaluation method we will be able to independently calculate alternative foils in the future. One possible future scenario would be to declare the foils as climate-neutral by means of CO2 compensation through climate protection projects.